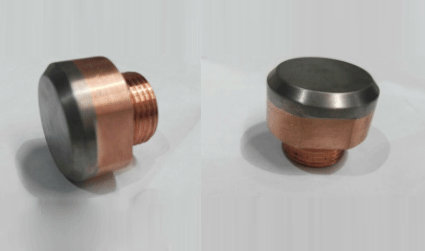

Stud nut electrode

Stud / nut welding electrode (projection welding electrode)

In projection welding (such as automotive industry, bridge construction), lots of sheets and work pieces need to be connected by nuts. This requires high quality nut welding electrodes with not only long service time, but also high strength, hardness and wear resistance.

Our nut welding electrode uses copper tungsten alloy that comprises 75% tungsten and 25% copper as electrode coating to keep its high wear resistance and loading endurance. Chromium Zirconium Copper shaft is used to ensure its high electrical and thermal conductivity.

Copper tungsten pillar

We also supply small copper tungsten pillars with the following sizes and tolerances (0, +0.05):

Size

| Dia. 1/2" × 1/4" | Dia. 1" × 3/4" |

| Dia. 5/8" × 1/4" | Dia. 1-1/4" × 1/4" |

| Dia. 3/4" × 1/4" | Dia. 1-1/8" × 1/4" |

| Dia. 7/8" × 1/4" | Dia. 1-3/8" × 1/4" |

| Dia. 1" × 1/4" | Dia. 1-1/2" × 1/4" |

| Material | Hardness (HRB) | Electrical Conductivity (%IACS) | RWMA |

| 75W25Cu | 98 | 45 | 10W3 |

Material

| Content (%wt.) | Density (g/cm3) | Hardness (HRB) | Electrical Conductivity (%IACS) | RWMA | Application |

| Cr:0.6-1% | 8.9 | 85 | 70 | C18200 | shaft |

| Cr: 0.5-1.5% Zr: 0.05-0.25% Cu: balance | 8.9 | 80 | 80 | C18150 | shaft |

| 75W25Cu | 14.6 | 98 | 45 | 10W3 | coating |

Related Products

- Silver Tungsten AlloySilver tungsten alloys are used in industrial and domestic circuit breaker applications where good weld and erosion resistance is important. The higher silver grades have higher conductivity, and the higher tungsten grades have greater erosion and weld...